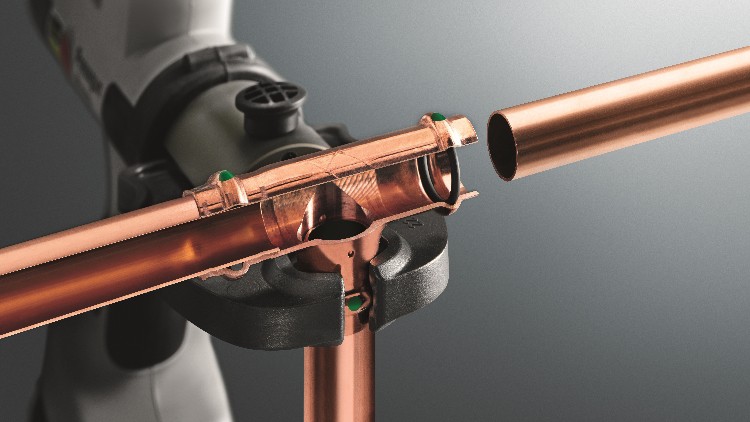

The apollopress line of fittings and valves feature pre lubricated seals and leak before press technology to ensure quick and confident connections.

Press fit copper fittings leaking.

16bar at 24c to 110c guarantee.

3 years for use with mini press tool pfzcte press fit straight coupler for use with gas systems.

The job we just completed had 3 4 1 1 1 4 1 1 2 and 2 propress fittings.

Every one of our fitters likes propress.

After finishing the piping we air tested at 100 psi with air.

Can handle temperatures up to 230 degrees centigrade so can also be used for read more.

How to stop leaks on threaded copper fittings.

Visit al s amazon plumbing shop http www amazon co uk shop dereton33 not the video you w.

Now we hear from viega one of the world s most recognised and respected press systems as to why press systems have not only become popular but also highly successful.

15mm 28mm approvals.

We have been propressing for about 4 years and no one has ever had a leak on a propress fitting until now.

Semantically pro press joints have less resiliency.

It was said that pro press fittings will not leak unless moved in some manner and that the failure rate is closer to 0 than 1 in static applications.

It has since grown to be one of.

Iwiss iws 1632af plumbing copper pipe crimper press tube tools with 1 2 3 4 1 jaws suitable for viega copper only pro press elkhart conex pipe fittings 4 5 out of 5 stars 42 199 99 199.

To our suprise we had a lot of leaks on the 2 propress.

Why they leak and how to fix them.

Copper yellow epdm olive size.

In the summer issue of plumbing connection we highlighted the issue of crimp fittings being banned on south australian government jobs.

Viega is a family owned company established in 1899.

Bsi kitemark gvdw operating pressure.

Compression fittings used on copper pipe are easy to fit together and remove.

Poor sealing of threaded pipe fittings causes leaking.

Just like with the brass fittings use a thread tape or thread compound to seal any leakage coming through the threads.

To address this problem you need to ensure the leaking threaded copper fitting is properly sealed.

I am not sure if or how pro press is engineered to accomodate the stress associated with cyclic reactions and thermal expansion.